Video goes behind the scenes of Tesla Cybertruck construction, including shaping steel door panels

YouTuber Sandy Munro showed viewers Tesla’s Cybertrucks being made. Suzanne Cordeiro

A Tesla VP took a YouTuber through part of the process of crafting the Cybertruck.

Auto expert Sandy Munro’s video shows how the massive panels are formed out of stainless steel.

Elon Musk has previously said the vehicle caused production hurdles due to its unique design.

Auto expert Sandy Munro shared a tour of part of Tesla’s Cybertruck production line on Monday, just weeks after customers received their first deliveries of the vehicles.

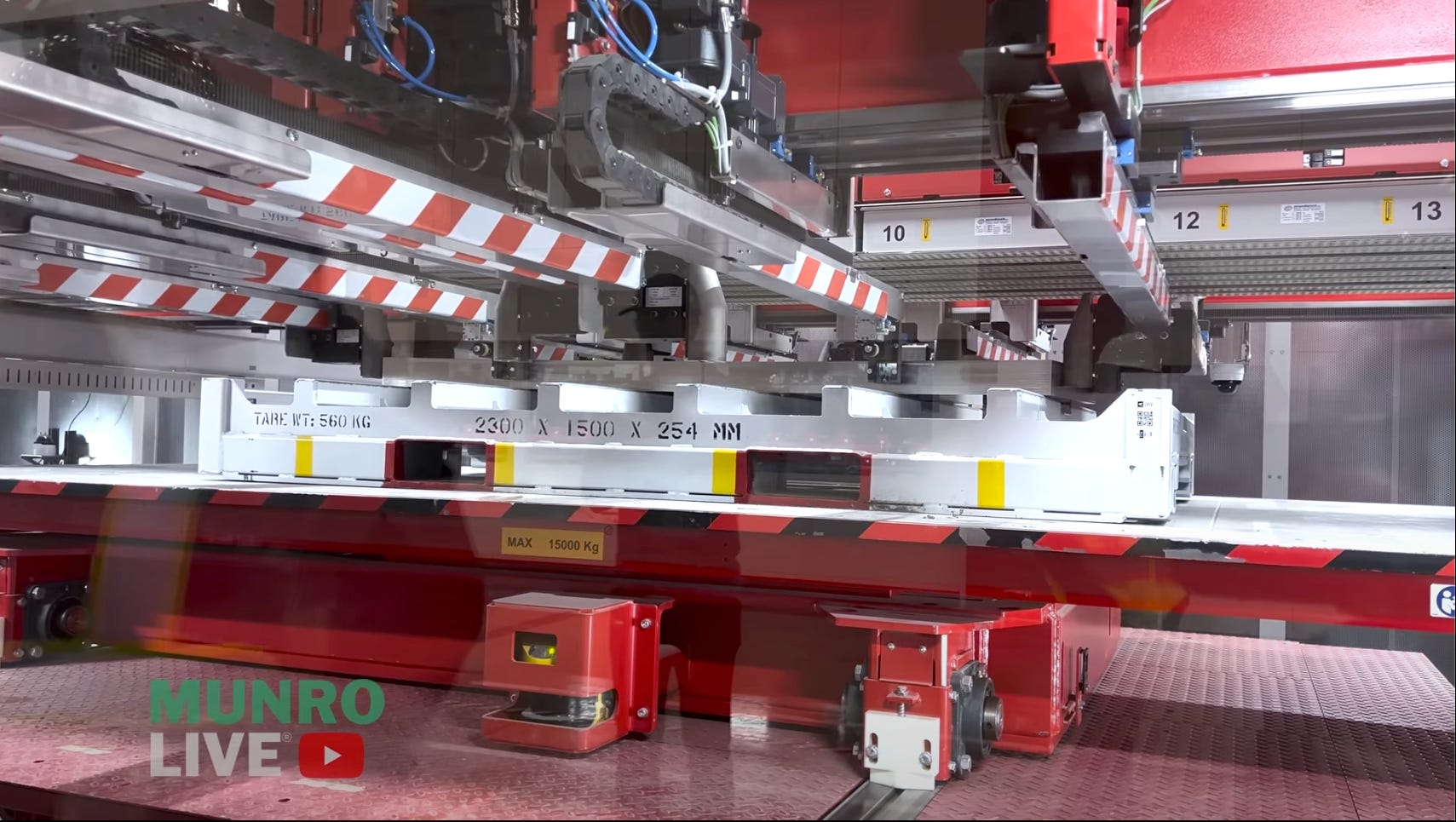

In the YouTube video, Tesla VP of vehicle engineering Lars Moravy showed Munro how the electric-car maker builds some of the stainless steel panels for the Cybertruck at the company’s gigafactory in Austin, Texas.

The stainless steel starts out in massive coils.

The Cybertruck’s stainless steel metal starts out as a large coil. Courtesy of Munro Live

Then these are unwound on a line and flattened, according to the video.

The large coils of stainless steel are flattened. Courtesy of Munro Live

After that, the metal is cut to fit the shape of the individual parts of the car and stacked, Moravy said.

The Cybertruck’s doors are 1.8 millimeters thick, though the rest of the truck is made out of 1.4 millimeter-thick metal, according to Moravy. For those concerned whether that’s safe enough, Tesla has said the vehicle is thick enough to stop a bullet. The truck even has an option for fixed bulletproof glass windows, according to Elon Musk.

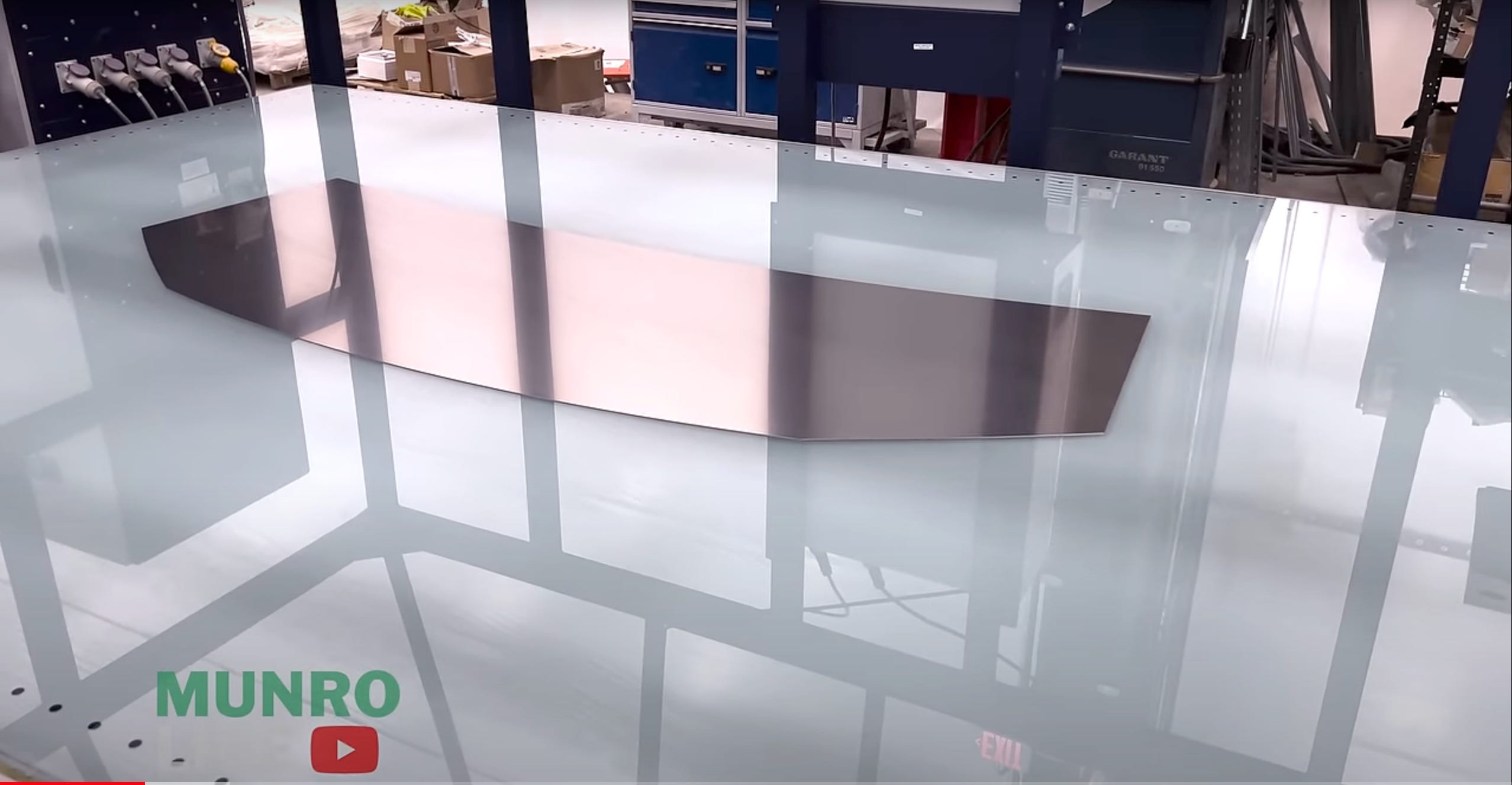

Tesla showed Sandy Munro how its Cybertruck doors are made. Courtesy of Munro Live

After the parts are cut, some are quality checked to try to ensure the factory matches the level of precision Musk has pushed for, one worker said in the video. In August, the Tesla CEO reportedly told staff that any variations in the truck would show up “like a sore thumb.”

Tesla does periodic quality control checks. Courtesy of Munro Live

Moravy also took Munro through the factory’s hot stamping process and later showed how the truck’s exterior panels are bent into their final shape.

Munro took a peek at the doors after they had been bent into shape. Courtesy of Munro Live

A Tesla spokesperson did not respond to a request for comment from Business Insider.

Tesla delivered its first dozen Cybertrucks in November. Musk has said he aims for the company to eventually reach production of about a quarter million Cybertrucks per year.

The billionaire has however emphasized that the vehicle faces some production hurdles due to its unique shape and stainless steel exterior. A carmaker hasn’t built a stainless steel vehicle since the DeLorean was released in the 80s.

Do you work for Tesla or have insight to share? Reach out to the reporter from a non-work email at gkay@insider.com